What’s the reason of cutting fluid goes bad and smells bad?

When the machine tools whether it is a CNC Milling machine, CNC Lathe, Machining Center or Gantry type milling machine, is being processed, the cutting fluid will flush the guideway oil, lubricating oil and other foreign oil into the coolant tank, which contains suspended fines/chips and those foreign oil. If the cutting fluid is not treated in time, it may flow back to the machine motor and the workpiece, subject to cause damage to the motor and affecting the surface accuracy of the workpiece.

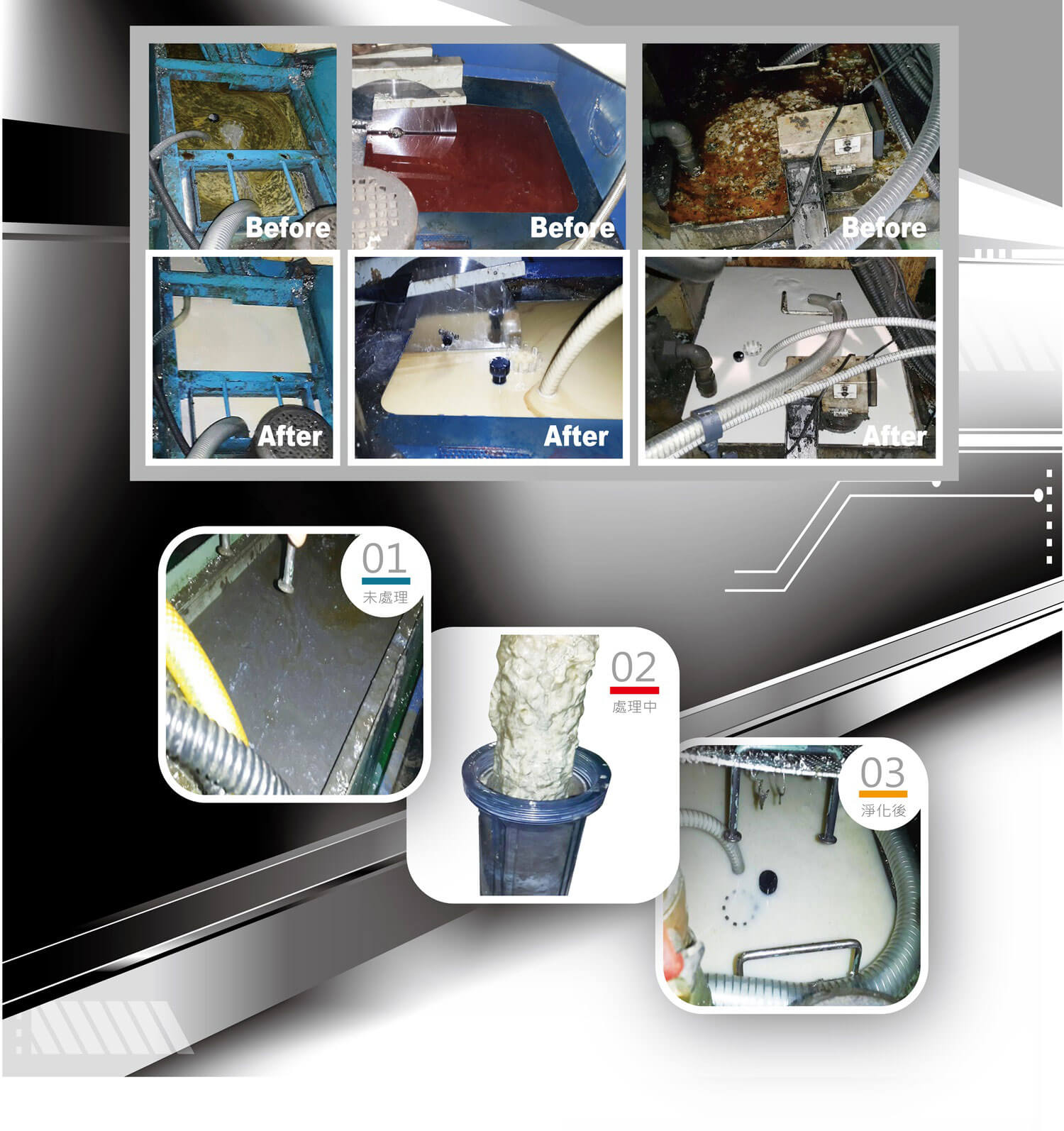

In addition, since the machine tools are not equipped with an environmentally friendly cutting fluid treatment device, slideway oil or foreign oil, etc... are mixed into the cutting fluid and cover the surface of the cutting fluid, lead to the cutting fluid to be unable to come into contact with the air, causing the cutting fluid to deteriorate, smell, and having problems of corrosion, foam generation, and operators skin allergies. Deteriorated cutting fluid or cutting fluid with insufficient concentration will also reduce tool life and affect the surface accuracy of the workpiece.

How to deal with tramp oil on cutting fluid?

Many CNC machines manufacturers nowadays provide a simple disc-type oil-water separator, commonly also known as an oil skimmer, as standard accessory. In addition, the oil-water separators sold on the market also include belt-type oil-water separators or chain-type oil-water separators. When using those simple types oil skimmer, remind you to pay special attention to regular inspection and cleaning, selecting appropriate cutting fluid, and regularly checking the concentration ratio, so as to ensure that the quality of the cutting fluid is not affected and avoid unnecessary problems.

Because the function of most oil-water separators is only to separate oil and water, the cutting fluid contains a large number of bacteria, which will still cause the cutting fluid to deteriorate and smell.

HC FENG Cutting Coolant Purification Equipment (Model:BEST-1) can not only filter impurities, separate oil and water, but also have the function of sterilization and deodorization with an ozone device. After actual use by customers, it has been proven that BEST-1 can effectively extend the service life of cutting fluid and reduce the risk of cutting fluid deterioration. It can reduce the odor generated, reduce the oil mist spraying on the machine and the oil dirt attached to the workpiece which causing skin allergies of the operator, improve the processing efficiency, stabilize the processing quality, extend the life of the tool, reduce the number of people cleaning the coolant tank and reduce the times of cutting fluid replacement, labor cost and cleaning time can also be saved, and the processing costs of waste oil and waste coolant recycling can be saved, too.