Application Industry

Total

8

-

Aerospace is one industry where machining operations face some of their toughest challenges. In the Aerospace industry standards are extremely strict, and there is no room for error, so close attention must be paid to the consistency of the equipment used for machining. One of the most important components of the machining process is the coolant.

-

The auto manufacturing industry is going through tremendous transformations. With the rapid transitioning to Electric Vehicles, and the increased use of robotics in manufacturing, manufacturers are paying close attention to the care and maintenance of their machining tools and machining centers. With the increased focus on green manufacturing and environmental issues, attention has also been turned to the coolants and lubricants used in machining processes.

-

To achieve high-quality work products and efficient manufacturing during machining operations, it is important that the coolants used during production remain free of contaminants. Properly maintained coolants help extend the life of cutting tools, prevent burning and smoking during machining tool operations, and ensure consistent high-quality products. To maintain the quality of coolant, various types of filtering systems are available for purifying and regenerating cooling fluids.

-

There are various machining operations to perform mechanical machining process. Whether to apply cutting, grinding, drilling, turning, milling from 5-axis to 9-axis, using vertical or horizontal lathe, multi-spindle or working in a machining center, cutting fluid is one of the top factors that determines the productivity. Cutting fluids are widely used for cooling, cleaning, anti-rust and lubricating of the work piece during machining.

-

Since the outbreak of covid-19 pandemic, the medical manufacturing industry started to face a tremendous change as medical supplies like masks and respirators were at their highest while manufacturers have to cope with the struggles of lack of materials, shipping delays and labor shortage. The medical industry is known for its high demand of perfection, giving no tolerance for errors.

-

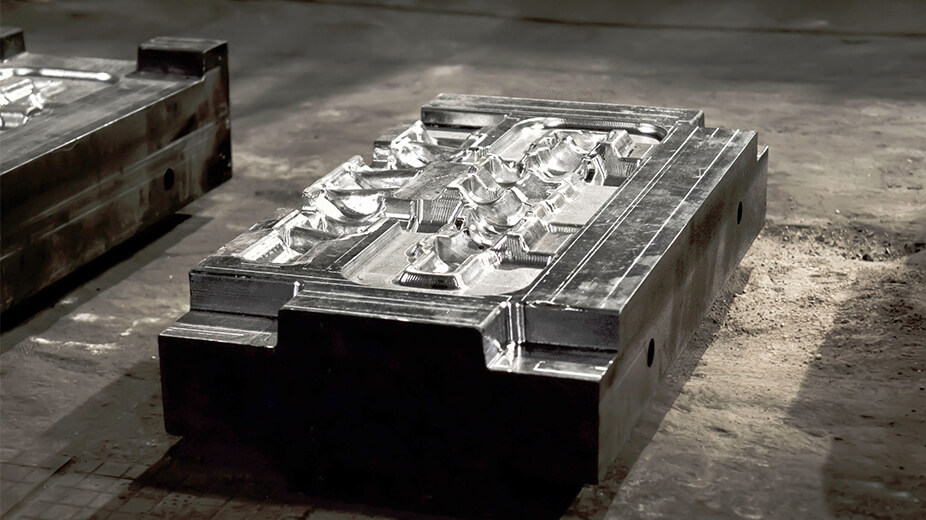

The Die casting is a machining process in which molten metal is injected into a mold under high pressure and hardened. Aluminum alloy made auto parts, bicycle spare parts, vehicle components and auto light are mostly made by die casting. It is one of popular metal processing methods. Further, the wastes and scrap materials from the machining are not much as they can be recycled in large part.

-

Why is MIT (Made in Taiwan) bicycles and bicycle parts so popular worldwide? The reasons are bicycle enthusiasts require accuracy, high performance, and durability. And the manufacturers of bike parts and accessories in Taiwan always meet their requirements.

-

Manufacturing companies, particularly those who fabricate fitness parts and metal parts for gym equipment are today facing intensified competition in quantities to satisfy the uncertain demand with best possible quality, price, and service.